Our scientists have developed a new coating process for activated electrodes

For more stable, efficient and cost effective performance

In the New Energy Market, Jolt manufactures activated electrodes for alkaline water electrolysers (AWE), anion exchange membrane (AEM) electrolysers, CO2 electrolysers & certain battery applications.

For traditional electrochemical applications Jolt manufacturers electrodes for electrochlorination, marine applications, electrowinning and many more.

Our approach addresses the heart of the matter – like a high-performance microchip, but for the electrolysis industry

Leon Rizzi, Co-founder

Replacing traditional, expensive and resource-hungry electrode production

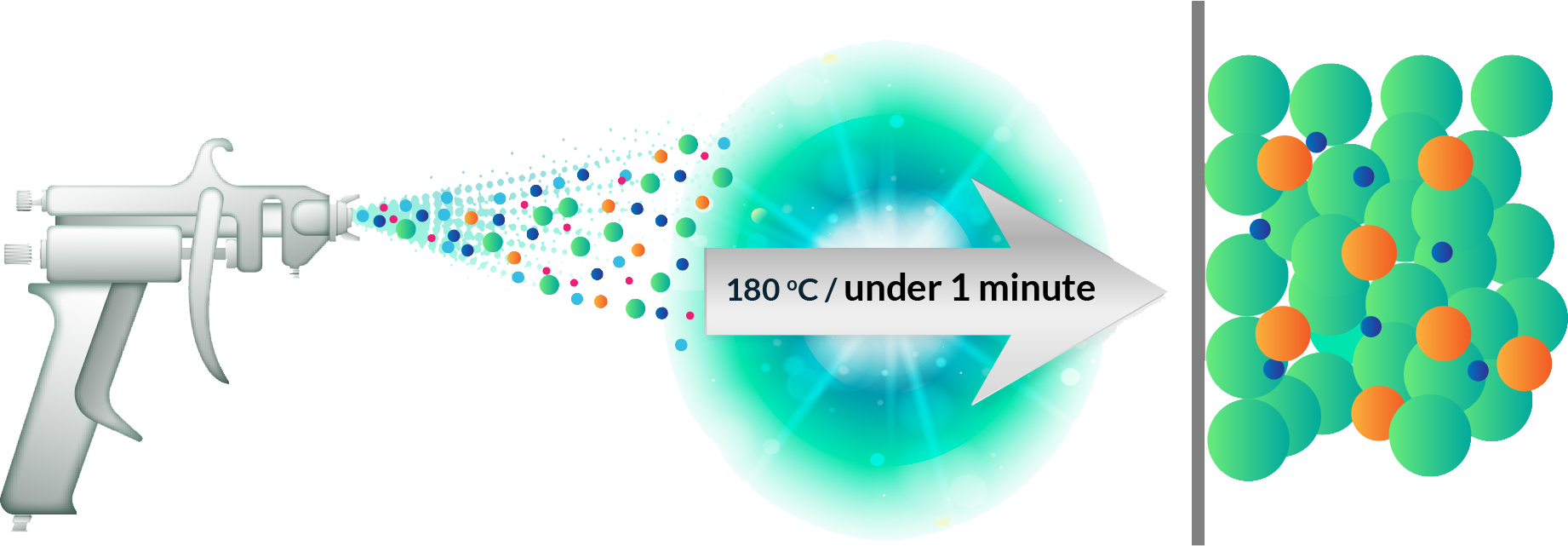

Using standard industrial catalysts, our Sparkfuze™ process

- creates an electrode in <1 minute

- uses low power

- results in higher ECSA & durability

- is more scalable & deployable globally

Meaning we can reduce or eliminate the use of precious metals and tailor coatings to include any desired catalyst mix.

Find out more

Green Hydrogen Electrodes

- PGM Free anodes for Alkaline Water Electrolysers

- PGM Free anodes for Anion Exchange Membrane Electrolysers

- Low PGM cathodes for Alkaline Water Electrolysers

- High PGM cathodes for Alkaline Water Electrolysers (maximum efficiency)

- Cathodes for Anion Exchange Membrane Electrolysers (wet cathode)

Chlorine Gas Evolution Electrodes

- Pool Electrochlorination

- Industrial Electrochlorination

- Disinfectant Solution Production

- Marine Applications

- Chloralkali

Oxygen Gas Evolution Electrodes

- Galvanic Plating

- Electrowinning

- Galvanizing

- Waste Water Treatment

- Cathodic Protection

Benefits for other

industries

We welcome technology partners for:

- Flow batteries

- Lithium refining

- Semi-conductors

A more efficient and sustainable process,

to improve catalytic performance

Standard manufacture

Numerous coatings

each takes

>1 hour

at

>400 ℃

Sparkfuze™

1 layer of coating

takes

< 1 minute

at

180 ℃

Find out more:

The future of our tech

We aim to transform from an electrode coating company to a material sciences company. Fully automating the identification, coating and testing of next gen catalysts within the next decade.

Sparkfuze™ is a coating platform on which we can build multiple solutions. Combined with AI, Sparkfuze/Solution Combustion can be used to automate catalyst design and robotised to create, deposit & screen candidate catalysts.

We welcome technology & commercial partners for

– Chlor-alkali

– Electrowinning / Metal Plating (ICs, Printed Circuits, Li Batteries)

– Water Purification

– eFuels

– Vanadium / Metal Air Redox Flow Batteries

– Carbon Reduction

– Platinization

– CCS & CCM for PPM

– Solar to H2 Production

Get in touch

FAQs

Who are Jolt?+

Jolt Solutions is a deep tech coating company. Our first multi-GW electrode manufacturing plant is based in Spain with more to follow. Jolt’s new patented process called Sparkfuze™ uses an exothermal reaction to impregnate catalysts into the surface of the substrate and create high ECSA layers.

What does Jolt actually do?+

Jolt Solutions has developed a proprietary process to apply catalyst coatings to electrodes. This allows for automated and scalable production of electrodes which are more durable, more efficient and cost effective.

Which sectors do Jolt support?+

Jolt’s first commercial offerings are focussed on AWE/AEM electrolysis for hydrogen production. Jolt is a strong supporter of the emerging Hydrogen Economy which is why we have started here. We identified a need for superior electrodes, particularly the anode. As a coating company however, we are expanding into other electrolysis applications. These include salt water chlorinators, waste water treatment, PEM electrolysis, electrowinning, cathodic protection and Chloralkali.

What scale is Jolt at?+

Our Barcelona factory will act as our pilot line and benchmarking hub. This line is designed to coat a variety of substrates with different catalysts. This means we will use semi-automated production with a capacity of up to 100,000m2/annum. Once business is established using the pilot line and has reached a certain volume, we will sign offtake agreements with customers and replicate this line close to or within customer production sites. Each line will be automated and will be capable of up to 400,000m2/annum. Deployment of such a line will take 8-9 months from the signing of an offtake agreement.

Have Jolt electrodes been used commercially or are you still a "lab animal"?+

Jolt electrodes have been used commercially in 10KW AEM stacks and in 500KW AWE demonstrator stacks. These products are available at scale having already been used to produce electrodes >4.5m2.

How consistent is the coating?+

The SparkfuzeTM coating process can deposit catalysts layer between 0.2-2mg/cm2. These layers have been shown to be consistent across the surface of the electrode giving uniform electrochemical activity.

Which substrates can the Sparkfuze™ process be used with?+

Jolt has created electrodes for AWE/AEM using nickel based substrates – Flynet, Expanded Mesh, Wire Mesh, Foam & Felt. We are now developing pre-treatments and coatings for titanium and stainless steel. The process is very gentle and has also successfully been used to coat Zirfon diaphragms.

Why does Jolt Solution tech matter for the green transition?+

Green Hydrogen is held back by a competitivity issue – it currently costs up to 4-5 times more than fossil fuels (cost target is $1-$1.50/kg). Reducing costs and increasing performance of electrodes are core to unlocking the sector.

We believe electrodes are the beating heart of electrolysis and fuel cells – and yet they still depend on last century tech. This is why it is electrochemistry, not engineering, that will determine the future of the Green Hydrogen sector. Jolt’s electro-chemical breakthrough can unlock the potential of green hydrogen.In an independent third-party report by Spanish energy consultancy “i-deals” (a subsidiary of Everis NTT Data), JOLT ́s catalytic coating technology was acknowledged as being: “…disruptive to the hydrogen sector with the ability to move to Level 4, disruptive to multiple sectors…(fuel cells, batteries, chlor-alkali)”

What stage is the Jolt team at?+

Jolt is moving fast for a deep tech startup. Commercial manufacturing in our Barcelona Research Centre started in Q2 2024; Fully automated production lines are ready to roll out at customers facilities under signed off-take agreements.

Our process, Sparkfuze™ is patented and tested – get in touch with our team to arrange a call to discuss how the Sparkfuze™ process can help your stack design.

How much cleaner and sustainable is the Jolt Solutions method?+

A Climentum due diligence sustainability report from 2023 concluded that: “ JOLT is likely to contribute positively to several SDGs.” Specifically goals 7,8,9, 11,12,13,5.

Our process emits > 75% less CO2 and our innovative tech platform allows us to create new catalysts that do not require rare earth materials.